Features

1. The PCD boring cutter features high processing precision and high work efficiency.

2. The PCD boring cutter can realize high speed cutting and hard material cutting.

3. With the features of high abrasive resistance and thermal conductivity, the boring cutter has a long service life. Its service life is 10 to 20 times that of tungsten carbide boring cutter.

Application

The PCD boring cutter is used to process tungsten carbide roller of various specifications.

Technical Specifications

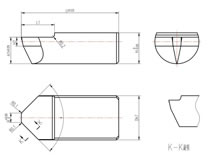

Specification of PCD Boring Cutter for Roller

| Drawing of PCD Boring Cutter for Roller | Dimension (mm) | ||||

| D | b | H2 | L | θ° | |

|

Φ4 | 0.7 | 3.4 | 7.98 | 70/80 |

| Φ4 | 0.8 | 3.4 | 9.68 | 80 | |

| Φ4.5 | 0.9 | 3.9 | 10.84 | 80 | |

PCD Milling Cutter for Acrylic

| Drawing | Dimension (mm) | ||||

| L | H | W | R | ||

| Precision | 34 | 12 | 6 | 1.2 | |

| Coarse | 34 | 12 | 6 | 6 | |

Specification of Boring Toolbar

| D | R | K | B | Thickness of Cutters |

| Φ3.6 | 2.76 | 4.56 | 3.2 | 1.3 |

| Φ3.6 | 2.62 | 4.42 | 3.2 | 1.3 |

| Φ3.6 | 2.67 | 4.47 | 3.2 | 1.3 |

| Φ4.5 | 3.67 | 5.92 | 4 | 1.4 |

| Φ4.5 | 3.48 | 5.73 | 4 | 1.4 |

| Φ4.5 | 3.52 | 5.77 | 4 | 1.4 |

Material

The PCD boring cutter uses PCD blanks and high quality tungsten carbide manufactured by world famous companies including Element Six (DeBeers, E6), DI (GE), ILJIN, SMITH, SUMITOMO and TOMEI.

Worldia is a PCD boring cutter manufacturer and supplier, based in China. We offer PCD boring cutters, Nikken glass cutters, glass cutting machines, etc. Our high quality products are offered at competitive prices. The full chain of manufacturing self-supported diamond die blanks and universal diamond scribing wheels can be completed in China, even in one city. Our lower manufacturing cost saves your purchasing cost. More details of each product are shown on the page with description.